Slurry Knife Gate Valve

100TP-SD

CWP 150 Two Piece Body Bolted

All the sealing is accomplished by the elastomeric sleeves in the valve housing

Bi-directional Natural Rubber Sleeved Valve

All the sealing is accomplished by the elastomeric sleeves in the valve housing

Bi-directional Natural Rubber Sleeved Valve

| Model # | 100TP-SD |

|---|---|

| Flow Direction | Bi-directional |

| Valve Size | 2” – 24” (50mm–600mm) |

| Design | Raised face body tapped flange in accordance with ANSI150,JIS10K, DIN PN10 and AS 2129 Table D & E |

| Pressure Rating & Operating Temperature | 3” – 16” (DN 80-400) operate at 150 psi (10.3 bar) / Up to 180°F (82°C). 18” - 24” (DN 450-600) operate at 90 psi (6.2 bar) / Up to 180°F (82°C). |

| Shutoff | 100% isolation, bubble tight in zero downstream leakage |

| Body | CF8, CF8M, CG3M, Duplex Stainless Steel, Special Alloy, NI-RESIST ASTM A439 TYPE-2, CS, WCB |

| Gate | 304,316 and Nickel based Non-Stick Overlay |

| Seat | Long lasting Natural Rubber Sleeves Seated |

| Packing | * Packingless |

| Actuator Options | Hand Wheel, Bevel Gear, Pneumatic Cylinder, Electric Motor Lever, Ratchet and Chain Wheel. |

| Advantage | -. Easy maintenance & Replaceable Seat and Sleeves. -. No seat cavity where solids can collect and prevent full gate closure -. The elastomeric seats have been engineered to provide a high degree of abrasion resistance and chemical compatibility. -. UHMW gate support liner, which can help provide smooth gate operation and alignment while eliminating body wear |

| Application | copper, gold, silver or phosphate. |

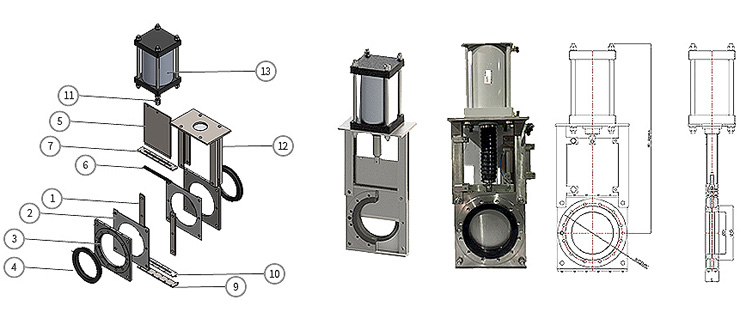

Design Features

| No. | PARTS | MATERIALS |

|---|---|---|

| 1 | Body Spacer | ASTM A240 SS316/ SS304 Carbon Steel Coated |

| 2 | Liner | UHMW |

| 3 | Body | ASTM A276 SS304 /316 Carbon Steel Coated |

| 4 | Seat Ring | Natural Rubber |

| 5 | Gate | ASTM A240 SS316/ SS304 |

| 6 | Secondary Seal | Silicone |

| 7 | Packing Gland Fasteners | ASTM A240 SS316/ SS304 |

| 9 | Drain Plate | ASTM A276 SS304 |

| 10 | Secondary Seal | Silicone |

| 11 | Clevis | ASTM A276 SS304 Carbon Steel Coated |

| 12 | Yoke | ASTM A240 SS316/ SS304 Carbon Steel Coated |

| 13 | Cylinder | ASTM A276 SS304 |

|   | Bolt | ASTM A240 SS304 |

|   | Nut | ASTM A240 SS304 |

|   | Washer | ASTM A240 SS304 |