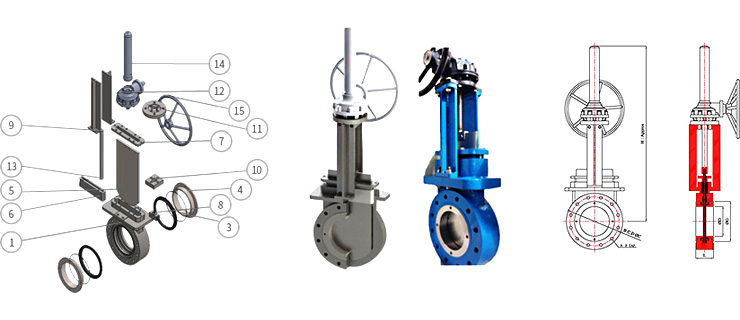

Knife Gate Valve

300M

Class 300 Single Cast Body

Metal Seated Uni-directional Valve

High Pressure Metal seated Unidirectional Knife Gate Valve

Metal Seated Uni-directional Valve

High Pressure Metal seated Unidirectional Knife Gate Valve

| Model # | 300M |

|---|---|

| Flow Direction | Uni-directional |

| Valve Size | 2” – 24” (50mm–600mm) |

| Design | MSS SP-61, 81, ASME B16.34 , B16.5 class 300lb Raised face body tapped flange in accordance with ANSI150, JIS10K, DIN PN10 and AS 2129 Table D & E |

| Pressure Rating | 740(720) psi (51 bar) CL300 |

| Shutoff | MSSP-81 and 135 |

| Body | CF8, CF8M, CG3M, Duplex Stainless Steel, Special Alloy, NI-RESIST ASTM A439 TYPE-2, CS, WCB |

| Gate | 304,316 and Nickel based Non-Stick Overlay |

| Seat | Metal Seated |

| Packing | Multiple rows of expanded PTFE with Graphite braided packing PTFE *Standard PTFE impregnated syntax is 450°F (230°C) *High Temperature Square Braided Packing to 1000°F(540°C)pH Range: 4–10 |

| Actuator Options | Hand Wheel, Bevel Gear, Pneumatic Cylinder, Electric Motor Lever, Ratchet and Chain Wheel. |

| Application | High pressure and abrasive slurries work in mining, oil sands , power, chemical processing |

Design Features

| No. | PARTS | MATERIALS |

|---|---|---|

| 1 | Body | ASTM A351 CF8M/ CF8 ASTM A216 WCB |

| 2 | Seat Seat O-ring |

EPDM, NBR, FKM(Viton) EPDM, NBR, FKM(Viton) |

| 4 | Seat Ring | ASTM A351 CF8M/ CF8 ASTM A216 WCB |

| 5 | Gate | ASTM A240 SS316/ SS304 |

| 6 | Packing | PTFE |

| 7 | Packing Gland | ASTM A351 CF8M/ CF8 ASTM A216 WCB |

| 8 | Clevis | ASTM A351 CF8 |

| 9 | Yoke (Arm. Leg, Posts) | ASTM A276 SS304 |

| 10 | Yoke Retainer (Pads) | ASTM A276 SS304 Carbon Steel Coated |

| 11 | Bevel Gear Mount Pad | ASTM A276 SS304 Carbon Steel Coated |

| 12 | Bevel Gear | Ductile Iron, ASTM A536 Coated |

| 13 | Stem | ASTM A276 SS304 |

| 14 | Stem Cover | Carbon Steel coated |

| 15 | Hand Wheel | Ductile Iron, ASTM A536 |

|   | Bolt | ASTM A240 SS304 |

|   | Nut | ASTM A240 SS304 |

|   | Washer | ASTM A240 SS304 |